Our services;

Pattern cutter/ Pattern maker

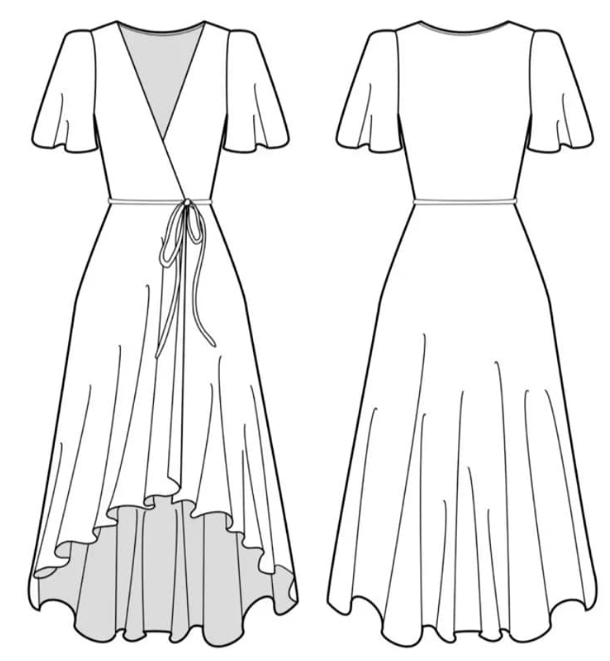

As a pattern cutter, I convert designers’ ideas and sketches into digital high-quality patterns for women’s, men’s, children’s or baby clothing. If desired including gradation and size specifications. Patterns are manufactured according to Rundschau/Mueller&Sohn’s pattern cutting techniques and made on a Lectra Cad Cam system which is convertible with all other Cad systems. It is also possible to work with 3D software, experience with Bowzwear. Familiar with working from toiles ore mock-ups and there is the possibility to digitize existing cardboard patterns. New developments are always made on the basis of a body list that is representative of the target group and that I can develop together with the client.

Product development

As a pattern maker I bring the design to life in collaboration with the stylist. Information transfer can take place by means of a supplied sketch, technical drawing, photo or basic model. This information is processed in a size specification sheet including gradation and possibly supported with additional explanations about finishes, seam symbols or recommended working methods. A third party will then manufacture a first sample. Usually this is the factory where the product will be produced, but can also be a local sample company. (for advice; PARTNERS) The sample is then measured and fitted after which corrections can be made. This work can be performed in my studio or as a freelance employee on location at the client premises.

Technical Fit Support

During a fitting there may be a need for technical insight; have we obtained the optimal fit, is the garment made according to the correct method or is there still room for improvement? By communicating effectively with a foreign pattern maker the right fit can be achieved with fewer samples also because the advice can possibly be supported by a basic pattern/ flat pattern that can serve as a starting point for the manufacturer and can also serve as a guideline for the brand.

When patterns are owned by the brand rather than the factory, it is easier to move production if necessary because the brand’s handwriting is captured in the “basic block” patterns.

Let's share knowledge

Pattern maker is a wonderful profession there is always a new field in which you can develop further, for example; baby clothes, maternity clothes, swimwear or the so-called usable soft goods (clothing with an extra function fulfilled by electronics) and finally, of course, there are also the current 3D developments. The biggest challenge in this profession is the combination between numeracy skills but also knowledge of the craft, pattern making and confection has been present since 1900, all this knowledge is digitally applied to the current fashion industry, reason enough for the need for knowledge transfer.

If there is sufficient interest (min. 6 people), workshops can be organized in my studio or at the customer’s. Conceivable topics can be; Creating patterns – Grading – Recognizing and correcting fitting errors.

The difference between wearable and wonderful seems small. It's a feeling you get when you put on your clothes; you are ready for the day to begin whatever situation it brings. You like to wear this, it is an extension of your personality without being bothered by wearing it.

This is, of course, caused by a good design and correct materials, but good designs must also be well executed. The first sample must reflexed the design, consideration must be given to silhouette, wearability of the garment, usability in the required situation and workmanship. What is beautiful and what is still possible in production or maybe there is another unknown option? Size series without loss of fit, correct digital transfer to the factory and control in production without unnecessary delays due to patterns which are incorret. The "fit" must be consistent and recognizable and appropriate to the target group.

Perhaps the difference between wearable and wonderful is technical support, which I am happy and specialized in to provide.

Miranda Galesloot

ABOUT ME

Pattern Cutter and Fitspecalist

“I love my job and it gives me great satisfaction if I have been able to contribute to the success of a new collection”

How does it work?

Pattern is printed on “heatseal paper” and then stapled together to show how influential a correct pattern is for a proper fit. We didn’t use a beautiful fabric, interlining ore ironing it is just paper…